סמינר מחלקתי של ד"ר בן אמיר- השפעת פרמטרי תהליך ייצור תוספים על המאפיינים הדינמיים של AlSi10Mg

Influence of Additive Manufacturing Process Parameters on the Dynamic Properties of AlSi10Mg

Wednesday June 18th 2025 at 14:00

Wolfson Building of Mechanical Engineering, Room 206

Abstract:

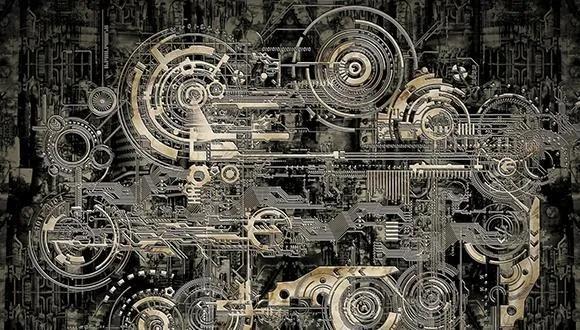

Additive manufacturing by selective laser melting (AM-SLM), better known as 3D printing, is an advanced manufacturing approach in which a structure is fabricated by successive thin powder layers melted by a focused laser beam. The aerospace and automotive sectors are especially interested in the AM-SLM of AlSi10Mg to enabling the quick production of complex and customized structures. The AM-SLM of AlSi10Mg process involves manipulating several key parameters such as laser power, scanning speed, hatching distance, scanning pattern, fabrication orientation, and postprocessing techniques.

Fabrication parameters show limited effects at quasi-static loading; however, this is not the case at dynamic rates. Therefore, this study utilizes several split Hopkinson bar systems, generating dynamic compression, tension and shear loading to characterize the effect of those key parameters on the dynamic behavior. This behavior was correlated with microstructure and crystallographic texture.

The first part of this study characterizes the parameters dictated by the process. We found at dynamic rates, distinct plastic behavior was observed at samples built in different orientations. Hence, this alloy was characterized as strain rate dependent and anisotropic. Moreover, a higher distance from the build platform resulted in a higher surface hardness and dynamic performance due to rapid cooling mechanisms. Stress relief treatment changes microstructure, causing uniform and low residual stresses, resulting in softening of the mechanical property, regardless of build height.

The second part addressed the following questions: What is the most affecting controllable parameter? And, How and why does it affect the dynamic mechanical properties? A comprehensive Taguchi-based design of experiments examines the influence of those parameters. Notably, fabrication orientation emerges as a significant factor affecting dynamic properties, where we observed a clear linear relationship between crack paths and maximum dynamic stress.

Each component of this study contributes to engineers' understanding of the dynamic response of AM-SLM AlSi10Mg, enabling more accurate estimations of its mechanical behavior for various applications.

Bio:

Dr. Ben Amir joined the Cambridge University Solid Mechanics group under Professor Vikram Deshpande as a Research Associate after receiving the Blavatnik Fellowship. Ben holds a Ph.D. in Mechanical Engineering from Ben-Gurion University of the Negev. Ben's exceptional doctoral work was recognized with prestigious awards, including the Kreitman Dean's Award and the Nehemiah Lev-Zion Fellowship from the Council for Higher Education.